How to Maintain Air Quality Sensors

Air quality sensors are important devices for monitoring pollutants such as PM2.5, PM10, VOCs, and CO₂ in the environment. They are widely used in homes, offices, industrial sites, and smart city systems. Sensor performance may decline due to dust, humidity, chemical contamination, or prolonged use. Therefore, regular maintenance is essential to ensure long-term stable operation and accurate data.

- Regularly Clean the Air Quality Sensor

- Avoid Extreme Environments

- Regularly Calibrate Air Quality Sensors

- Check Power Supply and Data Transmission

- Firmware and Software Update Maintenance

- Maintenance during Long-term Disuse

Regularly Clean the Air Quality Sensor

Three Steps of Cleaning

Regular cleaning is a basic step in maintaining air quality sensors. Dust, oil, and moisture are the main factors affecting sensor accuracy. It is recommended to clean the sensor every 1-3 months, with the specific frequency depending on environmental conditions.

- Surface cleaning: Use a soft-bristle brush or compressed air to remove dust from the sensor surface, avoiding particle blockage of the air intake.

- Internal cleaning: Some sensors (such as laser PM2.5 air quality sensors) may accumulate dust internally. Gently wipe the optical components with anhydrous alcohol (99% or higher), but handle with care to avoid damaging sensitive components.

- Filter inspection: If the sensor has a filter (such as some CO₂ sensors), it should be replaced or cleaned regularly to prevent blockages that could affect airflow.

Cleaning air quality sensors is an important maintenance step to ensure their long-term accurate operation. Since sensors are exposed to the air for extended periods, they can accumulate dust, oil, or other contaminants, which may affect their sensitivity and measurement accuracy. The following are the basic steps and precautions for cleaning air quality sensors.

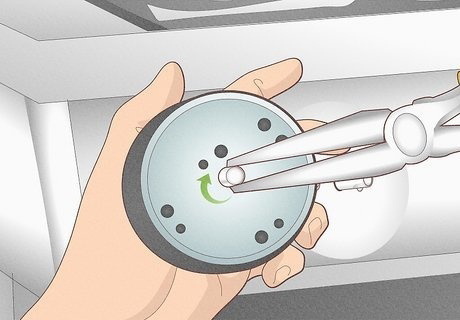

Specific Cleaning Procedures

Before cleaning, ensure the device is turned off and the power is disconnected to prevent electric shock or damage to the air quality sensor. For removable sensors, carefully remove them from the device according to the manual, gently remove large particles from the surface using a soft-bristle brush or compressed air, but be mindful of the force applied to avoid damaging sensitive components. If there are stubborn stains or oil stains on the sensor surface, use a cotton swab dipped in a small amount of alcohol or distilled water to gently wipe them off. Do not use corrosive cleaners or rinse directly with water, as this may damage the internal circuitry.

For non-removable sensors, use a vacuum cleaner with a small nozzle to clean the outer gaps, then wipe the housing with a slightly damp, lint-free cloth. After cleaning, ensure the sensor is completely dry before reinstallation or powering on. Additionally, regularly inspect the sensor's filter (if applicable) and replace it promptly to reduce the accumulation of contaminants. If data remains abnormal after cleaning, the sensor may be worn out, and you should contact the manufacturer for calibration or replacement. Regular maintenance can extend the sensor's lifespan and ensure the reliability of air quality monitoring.

Avoid Extreme Environments

The installation environment of air quality sensors has a significant impact on their performance. To maintain sensors properly, avoid exposing them to extreme temperatures or high humidity environments. Most air quality sensors operate normally within a temperature range of 0–50°C. Excessive humidity (>80%) may cause condensation, which can damage electronic components or optical components. Additionally, sensors should be kept away from areas with high concentrations of smoke, fumes, or chemical gases (such as cleaning agents, paint, etc.), as these pollutants may interfere with detection results and even shorten the sensor's lifespan.

Regularly calibrate air quality sensors

Calibration is a critical step in ensuring the accuracy of sensor data. Some high-precision sensors (such as CO₂ and VOC sensors) may require regular calibration for maintenance, especially electrochemical or NDIR (non-dispersive infrared) sensors. Calibration methods include:

- Automatic calibration: Some sensors have automatic baseline calibration functionality (e.g., CO₂ sensors require reset in fresh air at 400–500 ppm).

- Manual calibration: Calibration using standard gases or professional calibration equipment is recommended every 6–12 months, or as per the manufacturer's recommendations.

Check Power Supply and Data Transmission

The stability of the power supply and the reliability of data transmission are also important. Voltage fluctuations can affect air quality sensors, so it is recommended to use a regulated power supply or UPS (uninterruptible power supply) to ensure stable operation. At the same time, regularly comparing sensor data with data from other reliable devices or official monitoring stations can help identify potential deviations. If the data shows obvious abnormalities, troubleshoot the problem promptly and recalibrate or replace the sensor if necessary.

Firmware and Software Update Maintenance

For smart digital air quality sensors, firmware and software updates are equally important. Many IoT air quality sensors rely on software algorithms to optimize data, so regularly checking for firmware updates provided by the manufacturer and ensuring that the sensor is running the latest version can improve accuracy and functional stability.

Maintenance during Long-term Disuse

If the sensor needs to be disused for an extended period, proper storage methods can extend its lifespan. Before storage, the air quality sensor should be thoroughly cleaned and ensured to be completely dry. Store it in a dust-free, dry environment, away from direct sunlight or high temperatures. If the sensor is battery-powered, remove the batteries during long-term disuse to prevent leakage from corroding the circuitry.

In summary, good maintenance practices can significantly extend the service life of air quality sensors and ensure the reliability of monitoring data. By regularly cleaning, controlling the environment, calibrating, managing power, and updating software, you can effectively reduce the risk of failure and maintain the sensor's optimal performance. If you notice a significant decline in sensor performance or irreparable faults, it is recommended to contact ATO.com or a professional technician for assistance. If necessary, replace the sensor to ensure the accuracy and continuity of air quality monitoring.